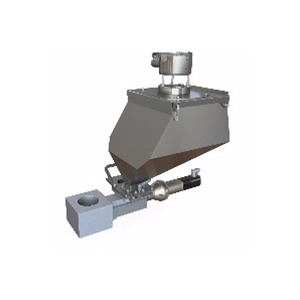

DCG-18-38 Gravimetric Dosing Unit

Overview

DCG-18-38 Gravimetric Dosing Unit

Digicolor dosing units now work more efficiently due to a new powerful motor. Robust components and a nitrided screw are combined with a self-optimizing control and a unique gravimetric hopper design. Due to this design the load cell is protected against external influences, allowing precise processes in an industrial environment

.

Based on continuous measuring of real throughput by the dosing control and automatic adjustment of masterbatch throughput overdosage is avoided at all times.

Technical Specifications:

- Hopper Volume: 3 / 6 Litre

- Material Flow: Up to 70kg/hr

- Dosing Screw Diameter: 23mm

- Power: 0.20kw

- Voltage: 230V / 50Hz

Advantages

- Accurate dosing through weighing – dosing accurance ±0.1% (depends on dosing quantity/material)

- Dosing depends on the received dosing and injection pulse of the injection moulding machine

- Up to 30% material saving compared to volumetric dosing systems

- Stainless steel hopper combination (internal/external hopper) with load cell inside

- Speed feedback allows nominal-actual value comparison and increases dosing accuracy

- Speed synchronization with the extruder

- Connection for visualization system (Modbus-TCP)

- Integrated venturi feeding control

- Intuitive operator guidance

- Suitable for all free flowing master and minibatches, additives as well as regrind

Product range

- DCG-18 throughput up to 7 kg/h, 1 component

- DCG-38 throughput up to 70 kg/h, 1 component